You are here: Home / English home / Products / Gear drive units / Mill gear drive units / D3500 / D3500 Z

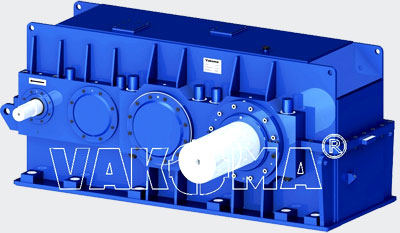

Model D3500/Z1 Mill Gear Drive and Model D3500/Z2 Mill Gear Drive

| Original manufacturer | GDW, SKET |

| Used for | Used for 2.6 m dia. x 13 m mills; Model D3500 gear drive unit with twin gears Model D3500/Z1 + Model D3500/Z1 twin gears |

| Rating / Motor rating | 810 kW (surge power 1,620 kW) |

| Design factor / Factor KA | 1.6 as per design method to TGL 10545, 10546 |

| Driving speed | 975 rpm |

| Transmission ratio | A1: 49.04 A2: 47.31 |

| Bearings fitted | Plain journal bearings |

| Weight of gear drive unit | approx. 48,500 kg |

| Rehabilitation capability of the original gear drive | New gears of converted configuration; welded helical gears. Replacement of antifriction gears |

Replacement

Newly developed Vakoma gear drive with hardened and ground teeth. Designed to DIN 3990 for factor KA = 2.0

Note

Vakoma Gear drive for potential replacement in project engineering. Foundation needs to be modified. An advanced auxiliary drive with a jaw clutch having a positioning mechanism could be supplied. A membrane clutch for connection to the mill could be accommodated in the design.

|

D3500 Z1 Helical gear unit Original drawingDownload PDF-file |

Model D3500/Z1 Gears and Model D3500/Z2

| Original manufacturer | GDW, SKET |

| Used for | Spare parts for gear with D3500 on the pinion shaft of the 2nd stage screwed spur gears of the 1st Stage (gear doubleobliquely) passed on. The 2nd stage was Sunderlandverzahnung. |

| Rating / Motor rating | 800 kW ( surge power 1,600 kW) |

| Design factor / Factor KA | 1.6 through 1.8 as per 1984 design methods (TGL 10545; 10546) |

| Driving speed | 975 rpm |

| Transmission ratio | 49.728 |

| Bearings fitted | Plain journal bearings |

| Weight of gear drive unit | approx. 54,000 kg |

| Rehabilitation capability of the original gear drive | New, re-designed welded helical gears would be supplied. The helical gears and the coupling star are a shrink-fit. A two-piece cover is necessary for the output shaft! |

Replacement Variant

Available as gears for installation in existing non-worn casings. It would be appropriate to renew the antifriction bearings as well.